Preventing Air Pollution and Global Warming

IBIS Project for Optimal Ship Operation and GHG-Emissions Reduction

The NYK Group is actively pursuing various initiatives across our entire company to achieve higher quality, safe, environmentally friendly operations.

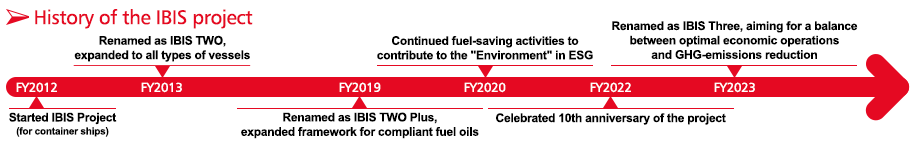

In fiscal 2012, we began the Innovative Bunker & Idle-time Saving (IBIS) project, which utilizes big data to drive a wide range of fuel-saving activities. As the scope of our activities expanded, the project evolved into IBIS-TWO and IBIS TWO Plus. In particular, since fiscal 2020, we have pursuing optimal economical vessel operation beyond the boundaries of group companies to contribute to the "Environment" in ESG through fuel-saving activities.

From fiscal 2023, the project name has been updated to IBIS Three, aiming to create both corporate and social value through the pursuit of optimal economic operations and GHG-emissions reduction. The improvement of operational efficiency through IBIS activities is an essential element for achieving our group's decarbonization goals. We will systematically promote the sharing of best practices, such as communication between offshore and onshore operators and remote support from onshore. Through these activities, we are challenging ourselves to achieve more advanced operations.

The logo was designed with the intention of protecting the blue earth through GHG-emission reduction, symbolized by the Ibis (stork) carrying the blue earth. The background's two-colored rings represent our corporate colors of blue and red, symbolizing infinity (∞) and the continuous efforts toward fuel-saving and GHG-emissions reduction, as well as the preservation of the blue earth for eternity.

- More Information:

-

- NYK's Ship Information Management System Recognized at 2015 Eco-Products Awards

- NYK's Ship Information Management System Receives Japan's 2015 Minister of the Environment Award

- NYK's Ship Information Management System Recognized with Special Award

- NYK and MTI Devise Energy-saving Adjustments that Significantly Reduced Emissions from Containerships

- The NYK Group ESG Story

- GHG Reduction

Challenges to Energy Conversion (LNG Fueled Vessel, LNG Bunkering Business, Zero Emission Fuels)

Please refer the relevant page of "Climate Change Initiatives."

- More Information:

Mechanisms to Increase Combustion Efficiency

The ideal shape of a ship for fuel-saving operations is one with minimal wave and wind resistance. However, ships must place priority on cargo tonnage and volume, which imposes constraints that make it difficult to achieve this ideal. Therefore, a number of appendages that can be added to ships to help them save fuel have been developed. One example is a propulsion-improvement unit that consists of multiple wings attached near the ship's propellers and rudder. The rotation of the propellers in the water creates a swirling flow that impairs propulsion. Attaching wings to the ship helps to recover this lost propulsion. Our propulsion-improvement unit (patented) was developed by the Monohakobi Technology Institute in February 2008 as part of a joint project, and experiments indicate that the unit has an energy-conservation effect of approximately 4-6 percent. We will be working in collaboration with shipyards and other parties to develop and deploy appendages that are optimized to individual ships, thus enabling them to achieve greater fuel savings.

Other energy efficient systems or adjustments

Make energy-saving-adjustments to be more energy efficient at slower speeds

(Left: Before remodeling) (Right: After remodeling)

To reduce energy consumption, ships often sail at a speed that is much slower than the average speed anticipated when the ship was designed and built. To make existing ships more energy efficient at these slower speeds, the NYK Group has been studying measures such as remodeling the ship's bulbous bow*1 and installing MT-FAST.

Big Data analyses using actual voyage data gathered over half a year after the implementation of improvements in June 2014 were conducted by the NYK Group, and a 23% reduction in CO2 emissions was confirmed. The conversion was also verified not to affect the safe operation of the vessel or the operating condition of the engine.

The NYK Group will also aim for further energy savings by ships by proceeding with construction based on this new approach now that effective methods (patented) for these operating conditions have been established.

- *1Bulbous bow

A protruding bulb at the front of a ship just below the waterline. The bulb modifies the way the water flows around the hull, reducing drag and thus increasing speed, range and fuel efficiency.

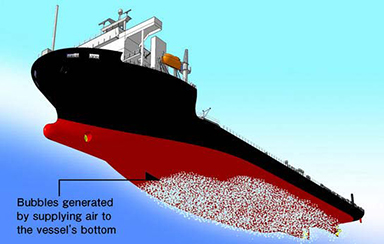

Saving Energy through "Bubbles" — Equipping Vessels with an Air-Lubrication System

Our air-lubrication system is an energy-saving technology that reduces friction between the hull and seawater by supplying air bubbles to the bottom of the vessel. In 2010, the NYK Group launched two module carriers*3, Yamato and Yamatai, which became the world's first operational ocean vessels equipped with an air-lubrication system based on an air-blower. In July 2012, the group introduced the coal carrier Soyo, which is equipped with a world first an air-lubrication system featuring a main engine scavenging-air bypass (related patent acquired). The group has confirmed that the air-blower-based system reduces CO2 emissions by an average of approximately 6 percent , while the system using a main engine scavenging air bypass is expected to reduce CO2 emissions between approximately 4 percent and 8 percent. Moreover, we have been making efforts to equip other types of vessels - such as newly built car carriers since 2014 - with this eco-friendly system.

Equipping vessels with air-lubrication systems has been highly commended both in Japan and abroad as an approach leading to the prevention of global warming.

We are currently proceeding with the installation of the system on other kinds of vessels. In fact, in May 2014 the NYK car carrier Aries Leader was delivered equipped with an air-lubrication system.

- *3Module carrier

Special heavy load carrier with roll-on, roll-off ramp way to transport thousand-ton prefabricated structures of plant facilities to be installed on oil/gas development sites or industrial locations.

NYK Recognized for Its Participation in Program to Improve Air Quality

NYK participates in the Green Flag Incentive Program that the Port of Long Beach has implemented to improve air quality.

These programs aim to reduce exhaust emissions from vessels by encouraging vessels to operate under 12 knots within a 20 or 40 nautical-mile zone.

NYK's compliance with the Long Beach program has been greater than 90 percent within the 40 nautical-mile zone since 2009.

Taking an active role in environmental regulations through development of new oil additive

NYK and Nippon Yuka Kogyo Co. Ltd. have been investigating the properties of VLSFO as one of the measures to comply with SOx emission requirements, and in May 2019 developed the sludge-dispersing fuel oil additive Yunic 800VLS.

Yunic 800VLS is effective against most of deteriorated compliant fuel oil, and with taking account into present fuel problem situations, we feel our main target need to be changed to reduction of fuel for contribution of environmental protection, from sludge trouble prevention.

Since we were aware of it, the both companies had been developing theYunic 800VLS "grade-up" version, which is having not only more powerful sludge dispersion characteristics to cover the rest of stubborn deterioration fuel, but fuel consumption reductions.

Yunic 800Eco enhances sludge dispersion and improves combustion. In three fuel consumption ratio reduction tests conducted with compliant fuel oils in Japan and overseas, we observed fuel consumption was reduced by up to 1.2% compared to when the additive was not used, and carbon monoxide (CO) emissions were also reduced.

We will continue to work to develop additives that are more fuel-efficient and versatile, while maintaining the current sludge dispersion effect, and contribute to the reduction of CO2 emissions from ships.

- More Information:

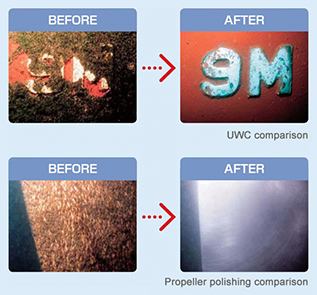

Removing extraneous matter and polishing propellers

Seaweed and crustaceans adhere to hulls and propellers, and result in increased propulsion resistance, which drops ship speed and increases fuel consumption. Ordinarily, antifouling paint is used on ship bottoms to prevent matter from adhering to the hull, but after the passage of time, organisms begin to adhere anyway, and underwater cleaning (UWC) is subsequently required. Extraneous matter adhering to propellers also limits propulsion efficiency, so propellers are polished as well. UWC results in a fuel-consumption savings of about 10%, and propeller polishing leads to a 1%-2% savings. NYK is actively enhancing its ships to reduce GHGs and preserve biological diversity.