Ship Recycling

Ship Recycling: Safety and Environmental Initiatives

The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, or simply the Hong Kong Convention, was adopted by the International Maritime Organization (IMO) in 2009 to minimize industrial accidents and environmental pollution when ships are dismantled. It has been decided that the requirements for entry into force will be achieved in Jun.2023,and that it will take effect on Jun.26,2025.

In order to build momentum for the early entry into force of the Convention, we have been a pioneer in incorporating the Convention's standards and working to establish the Convention as a standard among all stakeholders in ship recycling. Japan Marine Science Inc., a member of the NYK Group, has provided consulting services to 70 ship-recycling yards in India. The consulting has included civil engineering work for renovation, selection of equipment such as waste incinerators and hazardous material treatment equipment, assistance in bidding, and assistance in construction management in the "Preparatory Survey on the Ship Recycling Yard Improvement Project in India" conducted by JICA.

Ships contain a large amount of high-quality iron, and more than 90% of medium and large sized ships are recycled for construction materials, recycled materials, and used products. Appropriate disposal of these valuable recyclable resources is important for the realization of a circular economy.

The NYK Group's goal in ship recycling is to ensure that all ships around the world are properly dismantled in accordance with the standards of the Hong Kong Convention.

By being the first to adopt the standards of the convention, we are aiming to establish it as a standard for all stakeholders involved in ship recycling, and to increase the momentum for the convention's early entry into force.

In 2008, prior to the introduction of the convention, we established the following ship-recycling policy, which incorporates the final draft of the convention, and we will continue to improve it.

- An inventory of hazardous materials (IHM) is to be prepared for all ships owned by NYK and its group companies and kept on board. Ships that are likely to be dismantled will be given priority in the preparation of the IHM, and this document will be securely kept on board and presented at the time of delivery to the yard.

- We will visit the yards that have been issued a Statement of Compliance under the convention by the classification societies, and the yard will be certified by us if it meets our own standards, which take into consideration ISO 14001/9001/30000/45001 certification.

- We will periodically visit our certified yards to confirm that the level of environmental and occupational safety and health is maintained in accordance with our ship-recycling policy and standards.

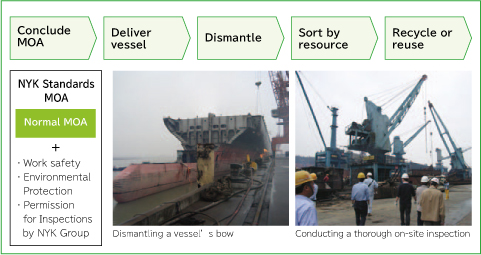

- We will use our own contract format for ship recycling, and after delivery to the yard, we will confirm the status of safety and environmental measures based on the contract and monitor the ship-recycling process.

Flow of ship recycling