Environmental Regulation

Environmental regulations will be strengthened sequentially in the future in the international shipping industry.The NYK Group ensures compliance with regulations and furthermore pursues a variety of initiatives to simultaneously realize safe vessel operations and environmental preservation.

Environmental Regulation Trends

To ensure compliance with the various environmental regulations in effect, the NYK Group also works to research, develop, and adopt cutting-edge technologies, make the most of vessel IoT and big data, and thereby make operations and allocation procedures more efficient.

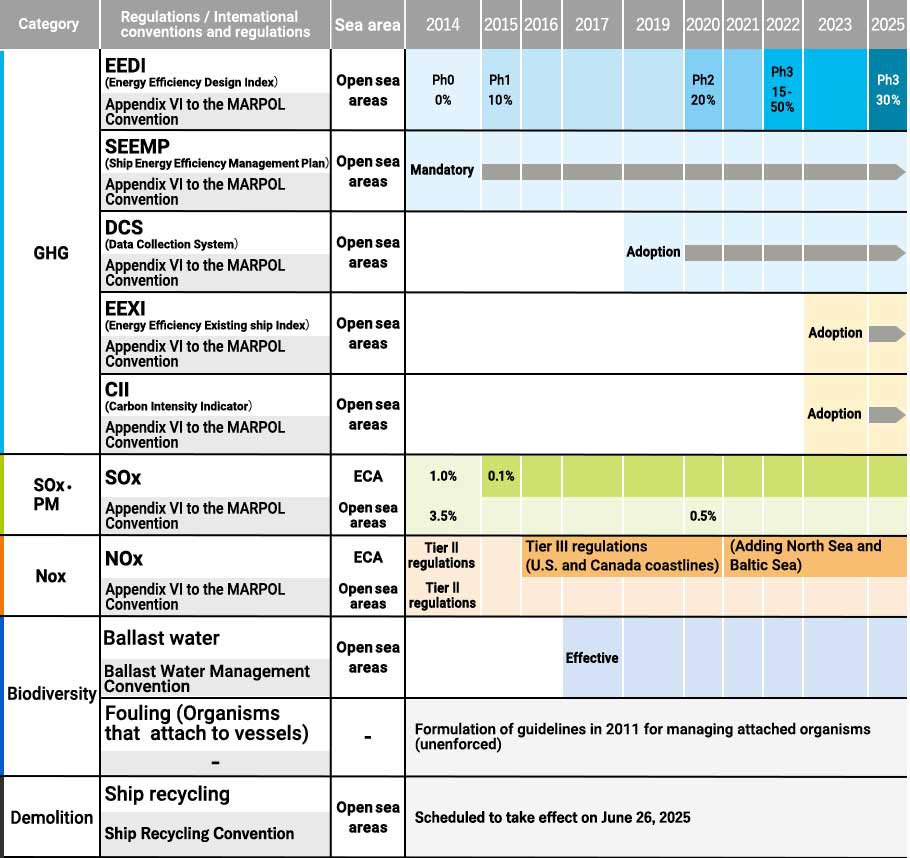

Timeline: Environmental Regulations

- ★General cargo, LNG carriers, cruise ships, and over 15,000 DWT gas carriers (LPG carriers); reduction rate is 30% Container ships; reduction rate is 15-50% depending on the size of the ship Other ships and under 15,000 DWT gas carriers; will be adopted in 2025; reduction rate is 30%

- *1EEDI

The Energy Efficiency Design Index (EEDI) is a formula for measuring a ship's CO2 emissions per ton-mile, based on the design of the ship being built, incorporating various parameters. - *2SEEMP

The Ship Energy Efficiency Management Plan (SEEMP) is an operational plan for improving energy efficiency on a voyage-specific basis - *3DCS

A Data Collection System (DCS) is used by shipping companies to report to the International Maritime Organization (IMO) on fuel consumption, voyage distances, and voyage times for all vessels of 5,000 gross tonnage or above operating internationally. A similar system (EU-MRV) was adopted in the EU from January 1, 2018, ahead of the IMO - *4EEXI

The Energy Efficiency existing Ship Index (EEXI) is a formula for ships already in service, as opposed to EEDI, which is used for newly built ships. - *5CII

The Carbon Intensity Indicator (CII) is used to promote CO2 reduction improvements by rating each ship type in five stages based on annual CO2 emission results. - *6ECA

Emission Control Areas (ECAs) are ocean areas in which restrictions on air pollutants are in effect

Preventing Air Pollution

SOx

The burning of fuel that contains sulphur results in the emission of sulphur oxide compounds (SOx).

IMO regulations aimed at reducing SOx emissions from vessels have come into force over the past several years.

In emission control areas in Europe, the U.S., and Canada - which are subject to even stricter regulations - the upper limit on sulphur concentration was lowered from 1.0% to 0.1%. The IMO has decided to apply stricter regulations, and is lower upper limits on sulphur concentration to 0.5% at sea.

To comply with these regulations, the Group considered the optimal method for each vessel of three options: using oil that complies with the regulations (low-sulphur fuel oil), installing an SOx scrubber (system for desulphurizing exhaust gas), or converting to LNG or other fuels. To ensure a safe and smooth switch to low-sulphur fuel oil beginning in January 2020, the Group done an internal project for sharing information on the timing and key points to note during the switch while also verifying the impact the compliant fuel oil. Our operating ships are operated well and no confused fuel oil supply.

NOx

Bunker oil, when burned, generates nitrogen oxide (NOx) compounds, which are greenhouse gases.

International Maritime Organization (IMO) regulations aimed at reducing vessels' NOx emissions have been in effect for several years, with the Tier II requirements becoming effective from 2011.

Furthermore, in the ECAs of the U.S. and Canada, vessels constructed on or after 1 January 2016 must comply with Tier III requirements. And in the ECAs of Europe, vessels constructed on or after 1 January 2021 must comply with Tier III requirements.

Preventing Global Warming

EEDI (Energy Efficiency Design Index)

Entering into force in 2013, the EEDI is an indicator for assessment of CO2 emissions per primary unit (ton-mile) based on specifications at the vessel design/construction stage. Calculation of the EEDI is mandatory for newly manufactured vessels, and a certificate indicating the EEDI specific to each vessel is issued. The CO2 reduction level (grams of CO2 per tonne mile) is tightened every five years to keep pace with technological developments of new efficiency and reduction measures.

SEEMP (Ship Energy Efficiency Management Plans)

This requirement related to reducing the greenhouse gas emissions from ships was adopted in July 2011 and requires all vessels to retain a SEEMP on board.

Every vessel makes Ship Energy Efficiency Management Plans before the start of each voyage.

Vessels operate accord to the SEEMP and review the plan after completing the voyage.

A SEEMP is one of the tools to carry out the PDCA cycle for efficient operation.

SEEMP is phased in from Part I and Part II (from 2019), and beginning in 2023, CII ratings will be required to be reported as Part III.

Please refer to the following description about Carbon Intensity Indicator (CII).

DCS (Data Collection System)

A data collection system (DCS) for the reporting and certification of data, such as fuel consumption, has been adopted, and will include existing ships.

The collection and reporting of related data will be obligatory from 2019.

EEXI (Energy Efficiency Existing Ship Index)

Entering into force on 1 January 2023, the Energy Efficiency Existing Ship Index (EEXI), which addresses the technical efficiency of ships, will limit CO2 emissions per unit of transportation for existing ships to help achieve the goals of the IMO's GHG strategy to reduce carbon intensity by 40% within the next decade up to 2030 and by 50% in total (70% intensity) up to 2050.

CII (Carbon Intensity Indicator)

Entering into force on 1 January 2023, the Carbon Intensity Indicator (CII) is a measure of how efficiently a ship transports goods or passengers. It is given in grams of CO2 emitted per cargo-carrying capacity and nautical mile. The ship will be given an annual rating ranging from A to E (A is best), and the rating thresholds will become increasingly stringent towards 2030.

Environmental Preservation

Ballast Water Management Convention

"The International Convention for the Control and Management of Ships' Ballast Water and Sediments (Ballast Water Management Convention)" entered into force on 8 September 2017 by the IMO (International Maritime Organization). To prevent harmful aquatic organisms and pathogens from cross-border transfer, each vessel will be required to have a Ballast Water Management System installed.

The NYK Group will continue to systematically install ballast water management system, and it is planned to complete installation on all ships by 2024.

Ship Recycling

To minimize industrial accidents and environmental pollution when ships are dismantled, the International Maritime Organization (IMO) adopted a ship-recycling convention in 2009.

It has been decided that the requirements for entry into force will be achieved in Jun.2023, and that it will take effect on Jun.26, 2025.

After the issuance of this regulation, all vessels will be required to keep the Inventory of Hazardous Materials (IHM) on board. The IHM indicates the location and volume of hazardous materials on the vessel.