Capturing Demand for LCO₂ Transport: Advancing All Three Transportation Modes for Practical Use

Released : Jun. 06, 2025

Updated : Jun. 06, 2025

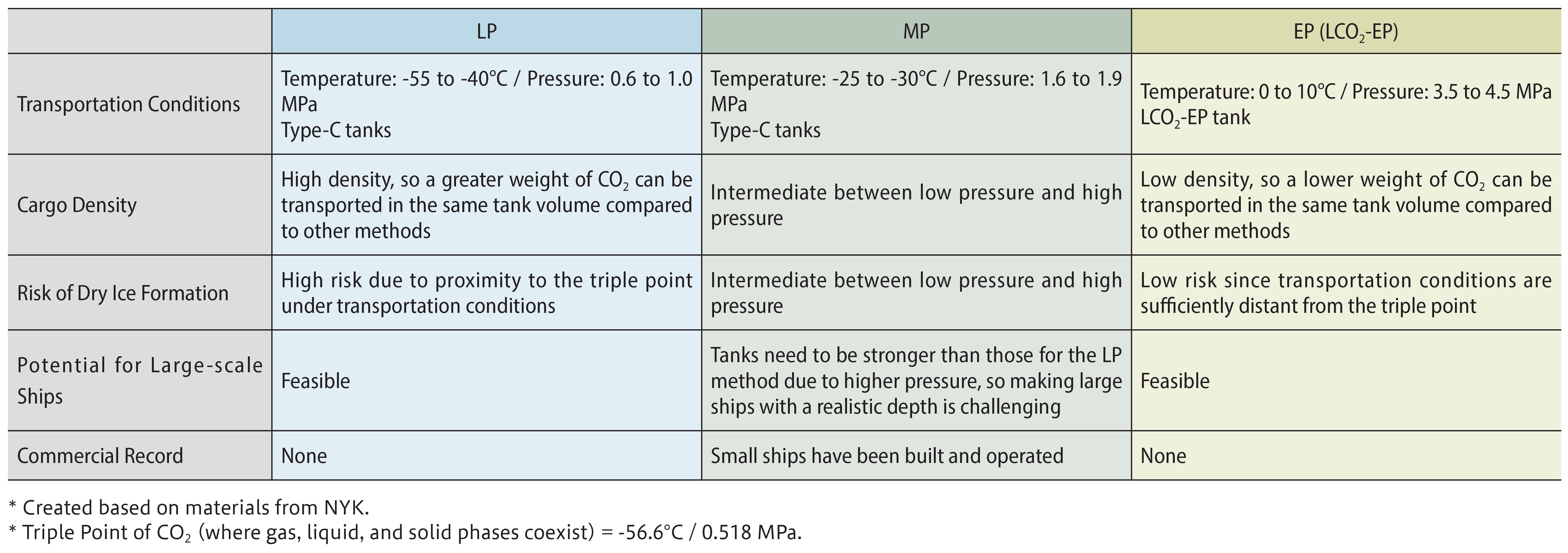

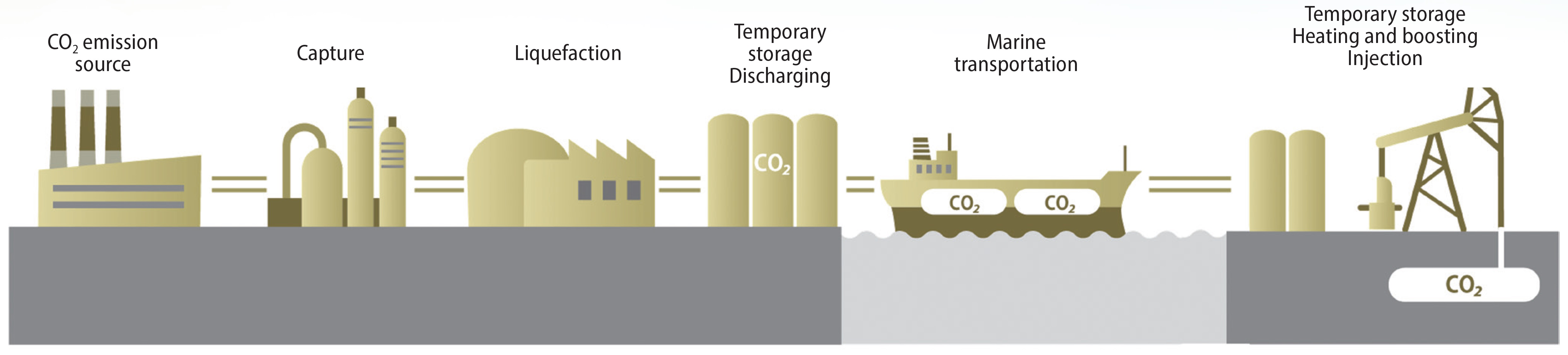

NYK is not only making rapid progress in decarbonizing and reducing carbon emissions in shipping but is also actively developing transportation technologies to support society’s transition to a low-carbon and decarbonized future. These initiatives focus on the field of Carbon dioxide Capture and Storage (CCS), which is regarded as a key solution for achieving carbon neutrality. Development of liquefied CO₂ (LCO₂) carriers is making rapid progress all around the globe to allow shipping large volumes of carbon dioxide (CO₂) captured and liquefied from power plants and factories for CCS purposes where CO₂ is injected and stored deep underground at designated storage sites. There are three transportation modes for LCO₂: “Low Pressure (LP),” “Medium Pressure (MP),” and “Elevated Pressure (EP).” The most suitable mode is selected for each CCS project, and NYK aims to meet future demand for LCO₂ transportation by offering all three modes

Development of Large Ships

Under the same pressure conditions, CO₂ does not require a cooling temperature as low as LNG for liquefaction. However, CO₂ does pose the challenge of being prone to turning into dry ice. The point at which gas, liquid, and solid phases coexist is called the “triple point.” Failing to control temperature and pressure properly can lead to the formation of dry ice. When dry ice forms within tanks or pipelines, it can cause blockages in the piping or damage to pumps. Addressing this issue is crucial for ensuring safe and effective transportation.

Currently, Medium Pressure (MP) is the only practical method for transporting LCO₂, and small ships with a capacity of less than 10,000m3 are already in operation. However, reducing CO₂ transportation costs in the future will require the construction of larger ships. Although the MP method has an ample construction track record, it poses challenges in scaling up due to the need for reinforced tanks to withstand relatively high pressures. The Low Pressure (LP) method, on the other hand, is considered more suitable when upscaling the ship size

NYK has been collaborating with Mitsubishi Shipbuilding Co., Ltd. since November 2021 to develop both of these LP and MP methods. In May 2022, the company obtained Approval in Principle (AiP) from Nippon Kaiji Kyokai (Class NK) for the basic design of ships of sizes small-to-medium and large. Additionally, NYK and Mitsubishi Shipbuilding jointly developed a dual-purpose ammonia and LCO₂ carrier and acquired AiP from Class NK in June 2023.

In September 2024, in collaboration with Mitsui O.S.K. Lines, Ltd. (MOL), Kawasaki Kisen Kaisha, Ltd. (“K” LINE), Nihon Shipyard Co., Ltd. (NSY), Mitsubishi Shipbuilding, Mitsui & Co., Ltd., and Mitsubishi Corporation, NYK obtained AiP from the American Bureau of Shipping (ABS) and Class NK for two ship designs: a 50,000m3 class and a 23,000m3 class, utilizing the LP method. NYK and six other companies are jointly working on establishing standard specifications and designs for LCO₂ carriers. They aim to develop a standard ship design to establish a domestic mass production system for large-scale CO₂ transportation starting in 2028.

Characteristics of Three LCO₂ Transportation Modes

Proprietary Technology: “LCO2-EP System”

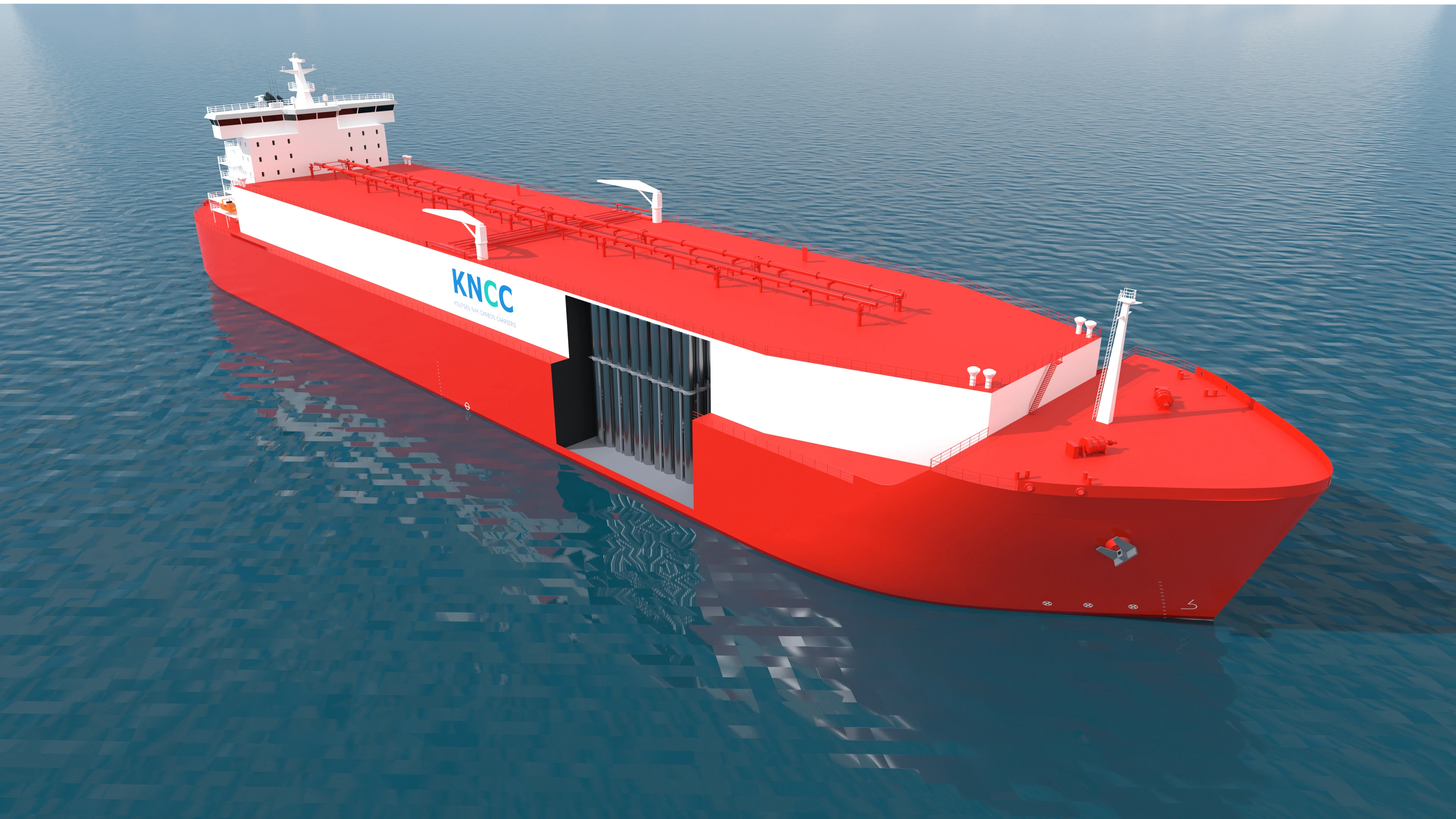

NYK is actively pursuing initiatives related to the Elevated Pressure (EP) method. In contrast to the LP and MP methods using cylindrical tanks, the “Liquefied CO₂-Elevated Pressure (LCO₂-EP) system” employs slender cylinder tanks (pressure vessels). This proprietary technology was developed by Knutsen NYK Carbon Carriers AS (KNCC) in a 50-50 joint venture with Norway’s Knutsen Group, a partner in NYK’s shuttle tanker business. The system received an AiP from the Norwegian classification society DNV in April 2022 and obtained a General Approval for Ship Application (GASA) for a detailed design from DNV in June 2023.

In September 2024, together with KNCC and JX Nippon Oil & Gas Exploration Corporation (now ENEOS Xplora Inc.), a successful demonstration experiment was conducted at KNCC’s demonstration test facility in Norway. This experiment utilized the isenthalpic expansion cooling and liquefaction process, which leverages the characteristics of the EP method to liquefy CO₂ and transfer it to the LCO₂-EP cargo tank. The process forms LCO₂ suitable for marine transportation by utilizing the temperature drop when captured CO₂ is depressurized. The success of this demonstration project will contribute to addressing key challenges in the commercialization of CCS, such as reducing the costs and site area required for the liquefaction and storage process.

Regarding the construction of LCO₂ carriers employing the EP method, joint studies with NSY are underway for the construction of a 40,000m3 ship. Additionally, in collaboration with KNCC and JFE Shoji Corporation, NYK has completed an assessment of production facilities, production capacity, and manufacturing costs for the steel materials required for LCO₂-EP cargo tanks and onshore temporary storage tanks. These efforts have ensured a stable supply of steel materials within the Asian region. NYK is steadily progressing toward realizing LCO₂ transportation using the EP method in addition to the LP and MP methods.

Overview of CCS Value Chain

Image of an LCO₂-EP carrier equipped with LCO₂-EP tank

Interview with the Project Manager

Leveraging Experience with Diverse Ship Types to Tackle New Cargo Challenges

Captains, Maritime New Business Extensive Support Team, Marine Group

Atsushi Nakazono and Prem Prakash

Atsushi Nakazono (left) and Prem Prakash (right)

—— Can you tell us how you became involved in the LCO₂-related business?

Nakazono: Since joining NYK in 2005, I have gained experience with a variety of ship types, including LNG carriers, bulk carriers, container ships, car carriers, and heavy-lift ships. From 2011, I was seconded for about three years to an affiliated company, where I also served on a drillship. My involvement in the LCO₂-related business began in 2020 when I was assigned to the Green Business Group. In this role, I collaborated with the sales team to organize and evaluate LCO₂ transportation modes. Additionally, within the group, I contributed to the development of next-generation fuel ships, such as ammonia and hydrogen-fueled ships, including LNG bunkering ships. Currently, my responsibilities encompass overall LNG bunkering operations, including supporting “KEYS Azalea,” which commenced operations in the Kyushu and Setouchi regions in 2024, and “Kaguya,” Japan’s first LNG bunkering ship operating in the Ise Bay area.

Prakash: I joined NYK in 2010 and embarked on VLCCs as a chief officer. In 2014, I was promoted to captain. In 2016, I was assigned to the NAV9000/QA team within the Marine Group (the team responsible for quality assurance of the unified safety standard “NAV9000,” introduced by NYK in 1998 for all operational ships). My role involved quality management of NYK-managed ships and conducting quality checks of ship-management companies. During this period, I gained valuable experience with various ship types, including gas carriers, wood chip carriers, and RORO ships, thus broadening my expertise significantly. Additionally, I contributed to the maintenance and improvement of the company’s safety management systems, which were undergoing digitalization. In 2021, I was transferred to the Maritime New Business Extensive Support Team, where I became involved in research on the marine transportation of LCO₂ using newly developed ship types. This research was conducted from commercial and operational perspectives and provided an excellent opportunity to foster close collaboration between the sales and marine engineering teams.

—— What experiences and insights have you gained that can be applied to the LCO₂-related business?

Nakazono: I have served on numerous LNG carriers, and my experience with cargo handling and operations on various types of ships, including drillships, is highly applicable. LCO₂ transportation requires knowledge of handling liquefied gases. In LNG operations, I have always paid close attention to the movement of cargo fluids within tanks, pipelines, and related equipment, as well as their temperature, pressure, and state—whether liquid or gas during cargo handling and management. One of the risks with LCO₂ is possible dry ice formation. My experience handling LNG helps me understand operational and design requirements to prevent such occurrences. Additionally, in the development of LCO₂ carriers, I contribute insights from the perspective of a marine engineer, such as identifying ship designs suitable for docking at power plants, ensuring safe navigation, and addressing regulations for domestic and cross-border transportation.

Prakash: My experience as a captain of VLCCs has been invaluable in managing complex cargo operations, adhering to safety standards, and mitigating onboard risks. LCO₂ is a new type of cargo with various risks and challenges. Broad experience in handling liquid and gas carriers is essential, and this knowledge helps in studying and mitigating risks associated with LCO₂ transportation, ultimately ensuring the highest safety standards. My time with the NAV9000/QA team has also deepened my understanding of international rules and regulations, which is crucial when applying the complex regulatory frameworks for operating LCO₂ carriers.

—— What excites you about working in this new business area of LCO₂?

Nakazono: The three modes for transporting LCO₂ vary depending on the nature of the project, regional factors, and routes. Though it involves a single type of ship, the diversity in transportation modes makes it a field that requires broad nautical knowledge, which is what I find fascinating about LCO₂ carriers.

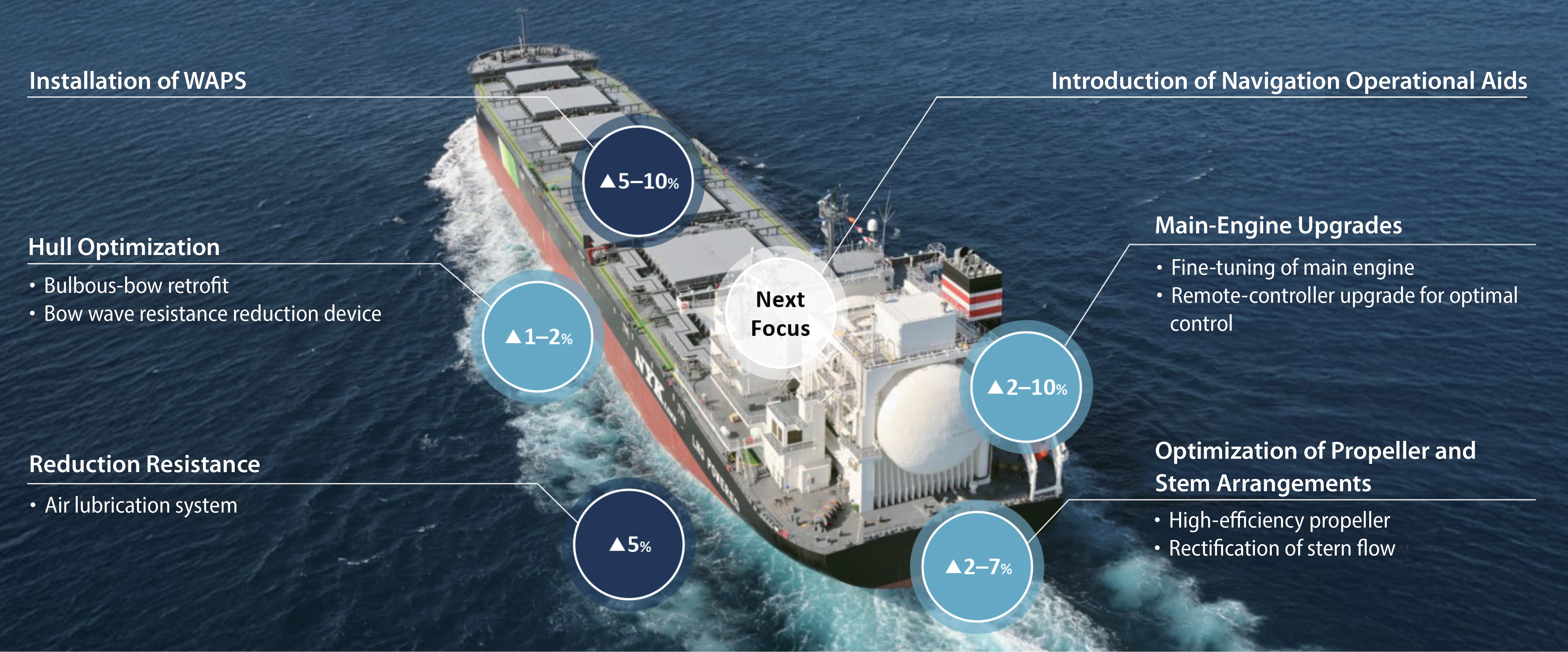

Prakash: LCO₂ transportation is rapidly growing as decarbonization progresses. Being a part of this industry means working at the forefront of innovation, which also contributes to career growth. Additionally, LCO₂ carriers incorporate various innovative technologies, such as LNG fuel and wind-assisted propulsion systems, providing valuable learning opportunities. Another attractive aspect is the collaborative teamwork required to drive these initiatives forward.

—— What makes working as a marine engineer at NYK appealing to you?

Nakazono: NYK operates a diverse range of ship types and provides numerous opportunities for onshore assignments, creating an environment where employees can leverage the experiences they gain in various roles. Everyone has the opportunity to acquire a wide array of experiences and develop broad expertise. Even if one doesn’t have all the answers, someone within the company often does, fostering a supportive and collaborative environment. Additionally, the company is always taking on new challenges, which makes working here incredibly appealing.

Prakash: At NYK, there are opportunities to learn and contribute across various divisions. The extensive knowledge gained through onboard roles can be effectively applied in onshore roles. Through my extensive experience as a seafarer, I have developed a solid foundation in risk assessment, safety management, and approaches to operational efficiency in ship operations. These skills prove to be crucial and highly valuable when tackling complex challenges, engaging in new projects, or working in onshore roles.

This article was re-edited from the Special Issue of KAIJI PRESS published on March 25, 2025.