Future-oriented Green Ship Recycling: Studying of Commercialization for Circular Economy and Decarbonization

Released : Jun. 03, 2025

Updated : Oct. 20, 2025

NYK has launched a project to commercialize an advanced green ship recycling business in collaboration with Oono Development Co., Ltd., a company engaged in industrial waste treatment, with the aim of promoting a circular economy and decarbonization. The project’s objective is to offer one-stop services focusing on environmental responsibility for the ship recycling process, from ship dismantling to industrial waste treatment. The plan calls for the commercialization of ship scrap recycling with an annual capacity of 300,000 tons (corresponding to about 20 Panamax ships)—the highest level in the world—by using Oono Development’s dry dock in Chita, Aichi prefecture. The plan aims to start the business by 2028

Ship Dismantling and Recycling

“Under its ESG (environment, society, and governance) policy and ‘Bringing value to life’ mission, the NYK Group has been contributing to decarbonization and tackling global warming by taking various measures to improve people’s lives,” says NYK President Takaya Soga. “Since NYK uses ships as tools of the trade, it is essential for us to not only make fuel conversions but also engage in recycling as part of our decarbonization efforts by dismantling ships and large offshore steel structures.” Because ships are made of high-quality steel, steel scrap from dismantled ships can be recycled. This is why ship dismantling is often referred to as “ship recycling.” “The trend of recycling steel scrap is important for society, and we are proud to be able to contribute to the process. We wish to continue the ongoing efforts as one of the symbolic segments of our business", continues the president. The environment surrounding ship recycling has been undergoing dramatic changes. As decarbonization trends accelerate globally, the steel industry has already started to shift from blast furnaces (used to make steel from iron ore) to electric furnaces (used to make steel from steel scrap). Therefore, the demand for steel scrap is expected to grow due to this shift. The value of steel scrap is also increasing as a high-quality iron resource because it contains only small amounts of impurities, which can be difficult to remove from molten steel. Ships use large quantities of high-quality steel, and more than 90% of medium and large vessels can be reused as construction materials, recycled materials, or used products. To realize sustainable recycling, there is a growing need for demolition methods that are safe, environmentally friendly, and efficient.

Efforts to establish a regulatory framework that creates an environment for sound ship recycling are also underway. The European Union (EU) Ship Recycling Regulation took effect in December 2013. Meanwhile, the International Maritime Organization (IMO) ship recycling convention will take effect in June 2025 to ensure environmental protection and occupational safety associated with ship dismantling. However, only a limited number of demolition yards in the world meet the criteria stipulated in those regulations.

This is why, in view of the ongoing environmental changes such as the need to promote decarbonization and a circular economy, as well as the growing public awareness of the need for environmental protection and occupational safety, NYK has changed course and decided to conduct a joint study on ship recycling in Japan.

Signing ceremony, from left to right: Hitoshi Nagasawa, Chairman, NYK: Takaya Soga, President, NYK: Yuji Yamashita, President, Oono Development: and Teruo Ohno, Chairman, Oono Development

A Synergism of Expertise

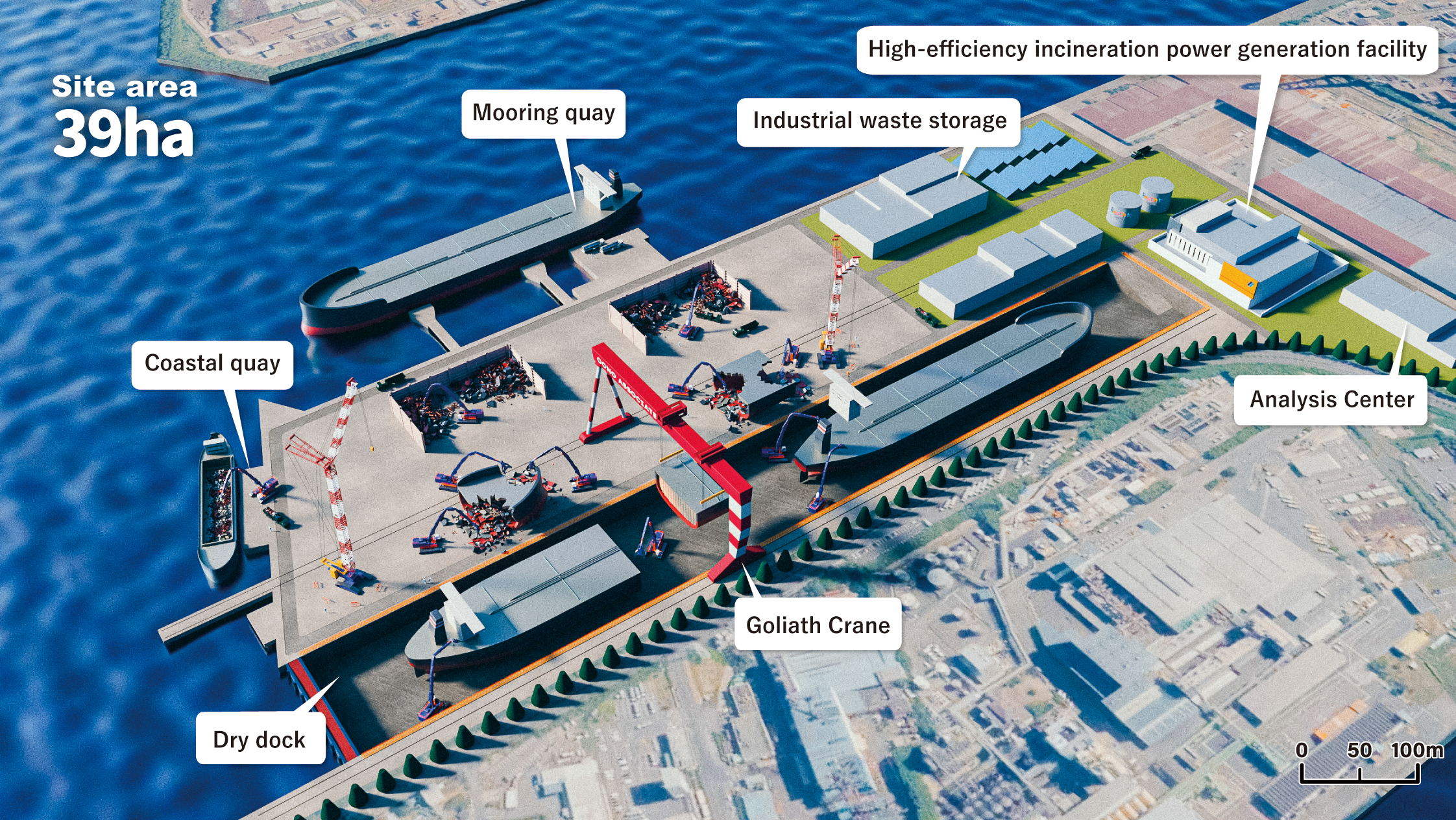

The future-oriented green ship recycling that NYK aims to carry out jointly with Oono Development is characterized by (1) a dry dock, (2) a demolition business, (3) heavy use of onshore equipment, and (4) effective use of an incineration power generation facility and a hazardous substance analysis center. This scheme provides a one-stop service focusing on environmental responsibility, from demolition to industrial waste treatment. This is made possible by taking NYK’s knowledge of the shipping business and ship recycling and Oono Development’s knowledge of onshore demolition and industrial waste treatment and combining it with a dry dock (depth: 810m; width: 92m; and height: 14.3m) capable of accommodating two VLCCs.

The scheme covers the entire recycling process, including the procurement of ships to dismantle, the dismantling of vessels, the sale of valuable resources such as steel scrap and used marine equipment, domestic transportation of steel scrap, and the final disposal of hazardous substances, including decontamination and landfill disposal. The aim is to realize environmentally friendly and efficient dismantling.

Environmental initiatives will include the removal of oil and other toxic substances at berths, along with proper waste management at the dry dock to prevent sea and soil contamination. A highly efficient incineration system will be installed at the dry dock site. Industrial waste generated from ship dismantling will be incinerated, and the electricity generated will be used for the dismantling work. Industrial waste that cannot be incinerated will be disposed of at controlled landfill sites under the management of Oono Development. High-quality steel scrap recovered from ships will be supplied to the steelmaking industry, contributing to decarbonization.

Planned safety measures include analyzing hazardous substances at the on-site analysis center, utilizing large equipment with cutter attachments—currently under development—at the dry dock to cut thick steel plates (steel plates used for the outer hulls of ships), and minimizing manual labor. The introduction of a 5G remote control system is also under consideration. These technologies will be key to the success of the business.

To realize the ship recycling business in Japan, problems such as high costs and labor shortages must be addressed. Therefore, the business plan will focus mainly on the largescale mechanization of demolition work and also address the automation of manual labor. Efforts will be made to develop new technologies, with the aim of not only ensuring safety but also achieving a shorter recycling work period and reducing costs.

The dismantling capacity of this business will be the largest in the world. In major ship-scrapping countries like India and Bangladesh, demolition relies mainly on manual labor. The number of ships that can be dismantled per yard is around three to five per year. The two companies plan to dismantle 20 ships per year by using a demolition method that relies on a large dry dock and mainly large equipment. There will be no restrictions on the type of ships that can be dismantled. Both coastal and oceangoing ships can be handled, and the dismantling of government ships will also be considered. Demand for the dismantling of large marine structures, such as floating offshore wind power generation structures, is also under consideration.

Image of Chita Dismantling Works, Oono Development

Finding Partners for Commercialization

To make the ship recycling business feasible, it is necessary to find partners such as shipowners willing to join the advanced green ship recycling scheme. The number of NYK ships dismantled yearly is not more than a few. Even if all those ships are dismantled at this dock, the target of 20 ships per year cannot be achieved. Therefore, making the dock available to various shipowners is essential. It will also be necessary to collaborate with the steel industry, to which steel scrap is to be sold, and other business collaborators, such as trading companies, which are essential for establishing a supply chain. To make the ship recycling business commercially viable, the two companies will seek collaborators from Japan and abroad.

Toward the goal of commercialization, NYK will continue its ongoing efforts, including acquiring certification of recycling facilities, as required under the ship recycling convention, and certification required for the demolition of EU-registered ships.

This article was re-edited from the Special Issue of KAIJI PRESS published on March 25, 2025.