Co-Creating the Future: An Environmentally and Human-Friendly Electric Propulsion Tugboat

Released : Oct. 31, 2025

Updated : Nov. 07, 2025

The NYK Group is set to build an electric propulsion tugboat equipped with lithium-ion batteries — a “tugboat of the future” designed to be gentle on both the environment and its crew. This innovative vessel will feature, among other advancements, Japan’s first domestically manufactured motor drive system for commercial ships. Though small in size, this tugboat represents a bold challenge to unlock new possibilities for Japan’s maritime industry.

Electric Propulsion: A Perfect Match for Tugboats and the Environment

Global environmental issues and labor shortages caused by Japan’s aging population are pressing challenges that the maritime industry must address. Against this backdrop, NYK launched its electric propulsion tugboat construction project.

Tugboats are small vessels that assist large ships in entering and leaving ports. They play a vital role in towing large vessels with ropes or pushing them from the bow to ensure safe and smooth berthing and departure. Logistics could come to a halt without tugboats, making them indispensable to our daily lives.

NYK Collection: Tugboats — The Mighty Power of Small Vessels | BVTL Magazine | NYK Line

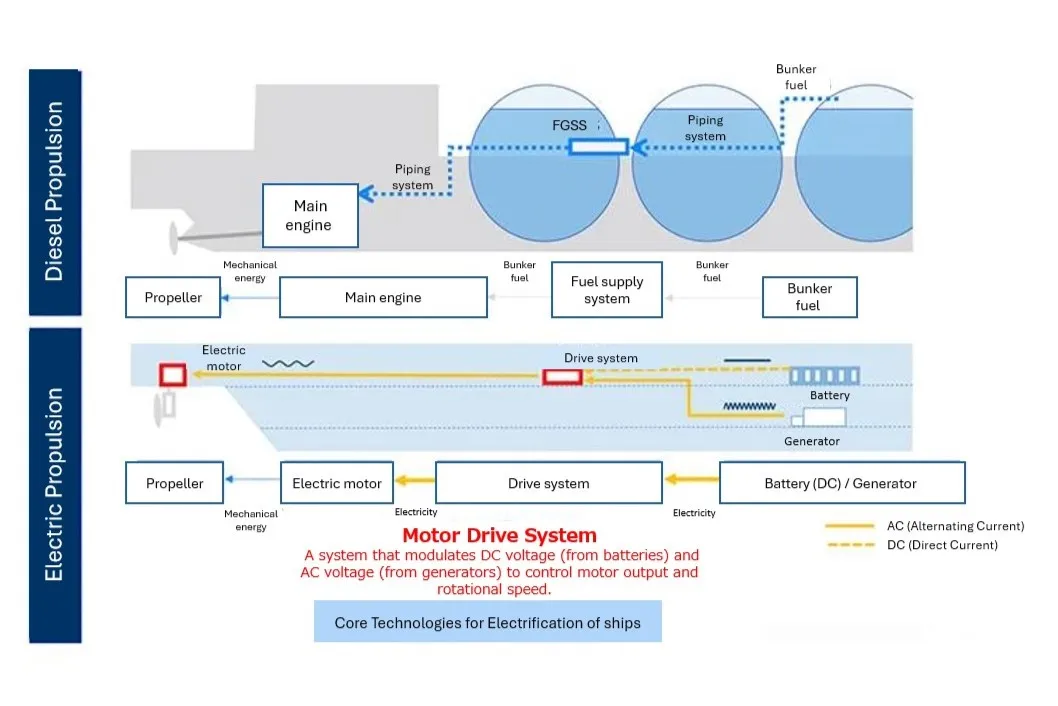

Traditionally, tugboats have used diesel propulsion systems, where heavy oil-fueled engines drive the propellers. In contrast, electric propulsion tugboats use electric motors powered primarily by lithium-ion batteries.

These tugboats are designed to operate using battery power alone for most operations, significantly reducing CO₂ emissions and making them environmentally friendly.

In 2015, the NYK Group launched Sakigake, Japan’s first LNG-fueled tugboat, which was retrofitted in 2024 to use low-emission ammonia fuel. Building on that experience, the Group is now taking on the challenge of constructing an electric propulsion tugboat.

Electric motors offer a significant advantage over fuel-powered engines in terms of controlling propeller rotation speed. For tugboats, which frequently operate in close proximity to large vessels and require precise maneuvering, electric propulsion systems hold great potential as a highly compatible solution.

Motor drive system used in electric propulsion. This new tugboat adopts a hybrid system combining lithium-ion batteries and generators as energy sources.

As you may know, decarbonization has become a global movement in environmental protection. However, electric propulsion systems are still rare in tugboats. Despite their many advantages, several hurdles remain.

One major challenge is space. Tugboats require sustained high power to tow large vessels, which means they need to carry a large number of batteries. To maintain a compact and maneuverable hull while securing battery space, the NYK Group is leveraging its full technological capabilities.

Development of a New Domestically Manufactured Motor Drive System

TMEIC Corporation, a leading domestic manufacturer with top-tier expertise in land-based motor drive systems, has embraced this project as an opportunity to develop a new high-capacity, high-efficiency motor with a compact water-cooled drive unit tailored for maritime applications.

This marks the first time a domestically manufactured motor drive system will be installed in an electric propulsion tugboat in Japan. The system uses a reluctance motor that does not rely on expensive rare earth materials, offering high efficiency, cost-effectiveness, and ease of maintenance — advantages not found in the permanent magnet motors commonly used by overseas manufacturers.

Domestic manufacturing also enables rapid maintenance responses and more attentive after-sales support. Moreover, the knowledge gained through domestic development contributes to strengthening Japan’s maritime industry as a whole.

“TMEIC Man” in front of the TMEIC Corporation

The TMEIC Corporation building

Japan’s First Tugboat Equipped with DPS

Another groundbreaking feature is the integration of a dynamic positioning system (DPS) — a first for Japanese tugboats.

DPS automatically controls the vessel by calculating and counteracting external forces such as wind and waves to keep the tugboat within a designated area.

Tugboats often face extended periods of “offshore waiting,” where they remain at sea for several hours during operations. During this time, crew members must manually adjust the vessel’s position, which can be physically and mentally taxing.

With DPS, the vessel can be held in place with the push of a button, greatly reducing the burden on crew members.

This initiative to improve working conditions has been selected for the Japanese government’s “Subsidy for the Development of Technologies to Promote Innovation in Coastal Shipping” (NX Subsidy), and continues to advance with industry-wide expectations.

End-to-End Development Within the NYK Group

One notable aspect of this project is that all processes are being carried out entirely within the NYK Group. Specifically, the Engineering Development Group has taken the lead as the system integrator, conducting the basic design, including the analysis of operational data and hull development. Based on this design, the vessel is being constructed by Keihin Dock Co., Ltd., and after completion, operations will be handled by Naikai Tug Boat Service Co., Ltd.

Completing all processes within the NYK Group allows detailed feedback to be exchanged at each stage, accumulating valuable insights for future electric propulsion vessel development.

Meeting of members of the electric propulsion tugboat project

Toward a Better Future for Japan’s Maritime Industry

Driven by a commitment to both environmental responsibility and improved working conditions, the project team is determined to create a tugboat that is as kind to people as it is to the environment.

Beyond environmental and operational benefits, there’s a vision to build a “cool” ship — a vessel that inspires pride among crew members and sparks interest in people who may not have had any prior connection to the maritime industry.

As Japan faces a serious labor shortage due to its aging population, innovative projects like this tugboat aim to reduce workloads and make the maritime sector more attractive to future generations.

The construction of Japan’s first electric propulsion tugboat equipped with a domestically manufactured motor drive system is steadily progressing, with operations scheduled to begin by the end of 2026. Stay tuned for further updates.