Improving Energy Efficiency Through Resistance Reduction and Engine Optimization: Centralized Review and Internal Deployment by Specialized Team

Released : May 28, 2025

Updated : Oct. 20, 2025

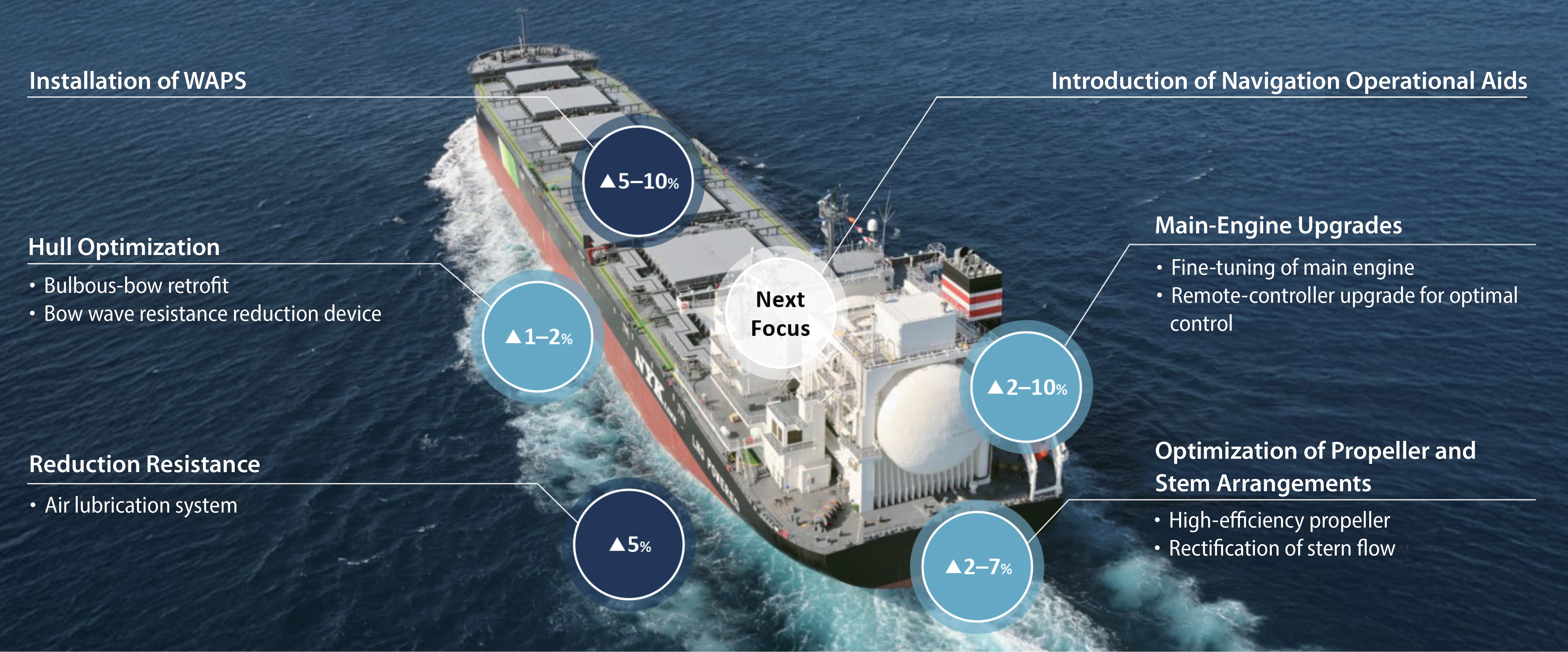

Key Technologies Under Consideration for Improving Energy Efficiency

In its medium-term management plan announced in 2023, NYK revised its Group-wide greenhouse gas (GHG) emissions reduction target (Scope 1 and 2) for fiscal 2030, increasing it from a 30% reduction compared to fiscal 2021 to an ambitious 45% reduction. Of the additional 15% reduction, 10% is planned to be achieved through improvements in energy efficiency. Key measures include reducing hull resistance and optimizing main engines. The company plans to prioritize the implementation of energy-saving technologies that are particularly effective under slow steaming conditions.

The Energy Efficiency Working Group was established to enhance energy efficiency. This organization is primarily led by the Decarbonization Group and consists of the Marine Group, Technical Group, and Marine Quality Control Teams of each business division. When introducing equipment contributing to performance improvement on vessels the working group conducts centralized reviews and shares the estimated implementation effects and analyses with the relevant business divisions.

Through past examinations to improve energy efficiency, the Decarbonization Promotion Team (hereinafter “the Team”) of the Decarbonization Group stated that they gained significant insights, particularly in reducing resistance and optimizing the engine’s performance.

For example, in terms of resistance reduction, it was found that implementing slow steaming to improve fuel efficiency produced limited additional effects, even when various devices were added to reduce hull resistance further. On the other hand, with regard to the wind-assisted propulsion system (WAPS), the Team observed the following: “During slow steaming, the likelihood of receiving wind from the bow is relatively low. Instead, the system is most effective when receiving wind from the side, making it highly effective even at reduced speeds.” As a result, the Team has decided to actively consider adopting such a system.

The research on main-engine optimization revealed that, compared to the planned speed of approximately 20 knots at the time of construction, the current actual sailing speed is significantly lower. This indicates significant potential for engine tuning to achieve optimal fuel efficiency at lower speeds. Based on this finding, the policy is to proceed with optimization for applicable Vessels.

For main-engine upgrades, the latest fuel-saving technologies will be applied to mechanically controlled engines to enhance performance during low- and medium-load operations at reduced speeds. Specifically, EcoCam technology will be adopted to improve engine efficiency by 1–2% by adjusting the opening and closing timing of exhaust valves, thereby increasing in-cylinder pressure for optimal performance at low and medium engine loads. Additionally, a Variable Injection Timing (VIT) system will be introduced, replacing the fuel injection timing of mechanically controlled engines with electronically controlled systems. This optimization of fuel-injection timing for low-load operation increases in-cylinder pressure, thereby improving fuel efficiency by 1–2%. For remote control of the main engine, the latest engine remote control system will be implemented to control the engine load automatically. This system will maximize engine performance.

To reduce resistance, efforts are underway to retrofit existing vessels with the energy-saving device SURF-BULB, which is attached to the rudder. This device improves fuel efficiency without affecting the ship’s maneuverability by adjusting the water flow generated by the propeller and converting the rotational flow behind the propeller into forward thrust.

The plan for Phase 1 (2024–2026) aims to reduce GHG emissions by 10%. During Phase 2 (2027–2030), the focus will shift toward achieving further reductions by implementing various technologies, such as wind-assisted propulsion systems and air lubrication systems. In Phase 1, the main engine upgrade will involve Mitsui E&S Co., Ltd., with remote control of the main engine managed by Nabtesco Corporation and Manta Marine Technologies. For stern appendages, IMC Co., Ltd. (licensed by the JMU Group) will be engaged.

This article was re-edited from the Special Issue of KAIJI PRESS published on March 25, 2025.