Creating the World’s First Ammonia-fueled Vessel Augmenting Safety Measures with Input from Marine Engineers

Released : May 14, 2025

Updated : Oct. 20, 2025

In August 2024, the world ’ s first ammonia-fueled vessel for commercial-use entered service in Tokyo Bay. This tugboat was developed by NYK and IHI Power Systems Co., Ltd. in collaboration with Nippon Kaiji Kyokai (ClassNK) as part of a Green Innovation (GI) Fund Project of the New Energy and Industrial Technology Development Organization (NEDO). Named Sakigake in 2015 with the hope that it would be a pioneer in the development of LNG-fueled vessels, the tugboat was retrofitted with a made-in-Japan engine capable of using ammonia, a next-generation fuel. Keeping the name of the original boat, Sakigake has resumed its voyage in the era of ammonia fuel.

From First in Japan to First in the World

Ammonia has been widely used for many years as a raw material for chemical products such as fertilizers, and NYK has long engaged in ammonia transport. In recent years, ammonia has begun to attract attention because it does not generate carbon dioxide (CO₂) when combusted, and efforts are being made worldwide to find ways to utilize ammonia as a fuel for ships.

In 2020, NYK set out to use ammonia as a maritime fuel. In October of the following year, NYK’s project to develop vessels equipped with domestically produced ammonia-fueled engines was adopted as a NEDO GI Fund Project, involving collaboration with related companies, including an engine manufacturer and a shipbuilder. The ammonia-fueled tugboat (A-Tug) Sakigake was the first vessel developed for the project. The vessel was developed by modifying a tugboat originally developed as Japan's first LNG-fueled vessel. After completing about eight years of safe operation, mainly in Yokohama Port and completed total 183 times of LNG bunkering, the LNG-fueled tugboat was docked at the Oppama Factory of Keihin Dock Co. Ltd., an NYK Group company, in October 2023 and converted into an ammonia-fueled tugboat. This conversion was completed in 2024.

In the project to prepare the main engine and other equipment for conversion into an ammonia-fueled vessel, the main members of the LNG-fueled tugboat development team reassembled to form an all-Japan project team. IHI Power Systems developed, manufactured, and test-ran the ammonia-fueled main engine. In May 2024, it successfully conducted a combustion test of a marine four-stroke engine, the first of its kind in the world, using fuel having an ammonia content of 80%. In July 2022, ClassNK gave an Approval-in-Principle (AiP) for the ammonia-fueled tugboat and assisted with safety-related technical verification and regulatory compliance. To supply the ammonia fuel, an organizational system for truck-to-ship bunkering at Yokohama Port was established in collaboration with JERA Co., Inc., a major electric power company, and Resonac Corporation, a chemical manufacturer.

One reason the first commercial ammonia-fueled vessel was made a reality not by building a new vessel but rather by modifying an existing one is that NYK aimed to produce the world’s first such vessel by reducing the construction lead time by recycling the hull of an existing vessel. There was also another reason why the challenging choice to carry out a modification was made. Since an LNG-fueled vessel produces about 25% to 30% less CO₂ emissions compared to using conventional heavy fuel oil, it was questionable whether all LNG-fueled vessels would be scrapped to achieve the goal of “zero emissions by 2050.” Thus, another purpose of the modification was to evaluate the technical feasibility of, and acquire knowledge about, converting an ammonia-fuel-ready vessel into an ammonia-fueled vessel.

Operated by Shin-Nippon Kaiyosha, an NYK Group company, the converted Sakigake conducts towing operations in Tokyo Bay. Based on the knowledge gained through the conversion project and ship operations, work is already underway to develop another ammonia-fueled vessel.

For the second ammonia-fueled vessel, it was decided to build an ammonia carrier because such ships do not need fuel supply facilities. While Sakigake is a coastal vessel, the next ship will be an oceangoing vessel. The new ship, to be built as part of another GI Fund Project, has been developed as a 40,000㎥ ammonia-fueled medium gas carrier (AFMGC) jointly with Japan Engine Corporation, Nihon Shipyard Co., Ltd. (NSY), IHI Power Systems, and ClassNK. It will be completed in November 2026 at the Ariake Shipyard of Japan Marine United Corporation (JMU). The aim is to achieve an overall reduction of greenhouse gas (GHG) emissions of 80% or more to contribute to the attainment of zero emissions by an oceangoing vessel.

Building-In Safety through Our Own Efforts

“We have been working to achieve a high level of safety through our own efforts,” says Senior Managing Executive Officer and Chief Executive of the Technical Headquarters Nobuhiro Kashima. It is generally thought that to put ammonia into practical use as a fuel for ships, three technical problems need to be addressed: overcoming flame-retardancy; treating nitrous oxide, which is a GHG; and handling toxicity.

Of these problems, the most vexing is the toxicity. If ammonia is to be used widely as a fuel, it is important to implement thorough safety measures so that accidents such as leaks do not threaten crew safety. In NYK’s ammonia-fueled vessel development project, a shipping company, a shipbuilder, an engine manufacturer, and a classification society contributed their respective expertise to work out safety measures to overcome the toxicity problem by both tangible and intangible measures. The development efforts involved identifying leakage risks and developing measures to prevent leakage from piping, as well as methods for detecting and coping with leaks through simulations. As a result of these efforts, solutions were found to facilitate the safe use of ammonia as a fuel.

The safety measures thus developed encompass not only tangible parts of the ship but also various intangible measures, such as developing ship operation management manuals and establishing maintenance methods for ammonia-fuel-related equipment. The study conducted to develop these measures incorporated considerable input from marine engineers. NYK’s chief engineers and engineers, who are professionals in operating marine engines, formed a task force and conducted risk evaluations and studies on safety measures from the viewpoint of marine engineers. As a result of these efforts, recommendations were made that considered the need to change conventional ship practices in terms of working methods and processes. These changes were reflected in the engine room layout and specifications.

“To minimize the need to enter the engine room, the number of cameras was increased so that the temperature and pressure of the engine room can be monitored from a remote location. The engine room (of the new ship) will look quite different from a typical engine room in a conventional ship,” says Naoto Takamori, a Marine Group assistance manager who led the task force.

Developing Bunkering Facilities to Promote Widespread Use

Ammonia carriers can obtain their fuel from their own tanks, but other types of vessels must procure fuel ammonia. Since establishing a fuel supply chain is necessary to spread the use of ammonia-fueled vessels, NYK aims to enter the ammonia fuel supply business. To this end, NYK is developing a bunkering boom, a piece of equipment for safely transferring liquid fuel from an ammonia bunkering vessel (ABV) to an ammonia-fueled vessel.

The bunkering boom is being developed jointly with TB Global Technologies Ltd. (TBG), a manufacturer of equipment for handling liquids (e.g., crude oil and natural gas). TBG holds the largest market share in Japan and in September 2024 obtained the world’s first AiP (according to TBG) for equipment handling ammonia fuel. To acquire the AiP, NYK provided design data for the in-house developed ABV and knowledge about Japan’s first LNG bunkering vessel Kaguya operated by Central LNG Marine Fuel Corporation, of which NYK is the largest shareholder, as well as knowledge about ammonia handling gained through the ammonia-transport business.

The bunkering boom's most crucial characteristic is that the connection between the ABV and an ammonia-fueled vessel can be instantly disconnected in an emergency. The safety device for supplying ammonia, a toxic chemical, developed by TBG substantially reduces the amount of ammonia dispersion in the event of an emergency disconnection.

Positioning the development of an ammonia-fueled vessel as the starting point for ship decarbonization, NYK plans to adopt ammonia fuel for various types of ships. NYK aims to complete a total of 15 ammonia-fueled vessels by 2033. The plans call for the start of construction of car carriers or bulkers in the latter half of the 2020s and the expansion of a fleet of ammonia-fueled vessels, including other types of ships, starting around 2035.

The knowledge gained from the first ship Sakigake will be used effectively to construct and operate the second and subsequent ships (oceangoing vessels) and to make rulemaking to that end. Following the use of LNG fuel as a transitional solution toward the goal of decarbonization, NYK aims to be a Sakigake (industry first) again in the use of ammonia fuel, which is the ultimate solution.

The ongoing A-Tug and AFMGC projects using ammonia-fueled Japan-made engines involve engine development, ship construction, and commercialization through collaboration among a Japanese shipping company, engine manufacturers, shipbuilders, and a classification society. The knowledge and technology gained through these projects will be widely disseminated. Doing so will contribute to decarbonizing not only NYK-owned vessels but also other ships from Japan and countries around the world.

Interview with the Project Manager

Honing One’s “Sense of Smell” for New Technologies

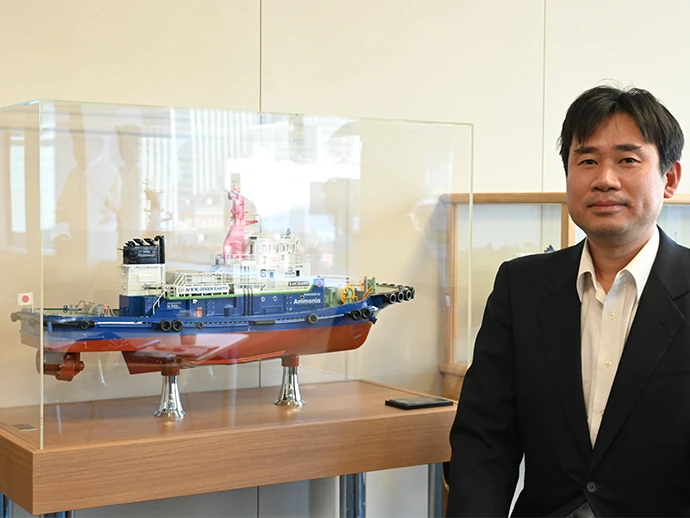

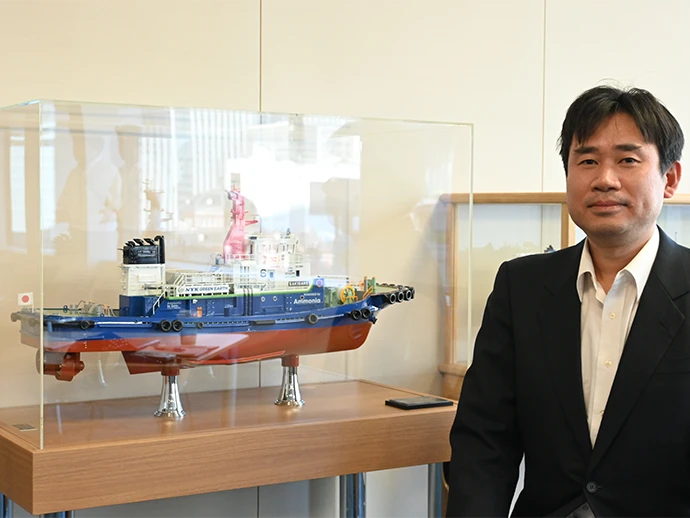

Naoto Takamori, Assistant Manager, Chief Engineer, Marine Group

––

How did you get involved with ammonia-fueled vessels?

When our company was working on two ammonia-fueled vessel projects involving a tugboat and an ammonia carrier, I was called upon to participate because of the need to create safe ships using the extensive knowledge and experience of crews and marine engineers, in addition to provide input from the sales department and the engineering department, which was involved in shipbuilding.

I have experience aboard more than ten ships, including VLCC, research, container, LNG, and ore carrier vessels. My onshore experience includes tasks related to new ships, union activities, and containership owner operations. The ammonia-fueled vessel scheme represents a new challenge that aims to obtain motive power by combusting ammonia. So, we work with engine manufacturers and shipyards, repeatedly conducting studies and verifications. Our initiatives involve various participants, not just manufacturers but administrative agencies, port authorities, and ammonia suppliers. So, in addition to transferring my knowledge and experience as a marine engineer, I aim to coordinate the project participants' activities by using my experience working onshore.

––

I heard that chief engineers and engineers made recommendations on safety measures for the ammonia-fueled vessels.

About 30 people got together to work out safety measures for ammonia fuel and prepared a report outlining their collected ideas in the spring of 2022. Our company has experience in gas-fired engines that use fuels like LNG. Basically, it is possible to adapt to using ammonia by drawing on that experience, but there are major differences from LNG fuel, including the toxicity and corrosiveness of ammonia. The toxicity is particularly important because there is a need for different kinds of precautions to protect crew members from health hazards.

For this reason, the first thing we did was to conduct research to collect information on past onshore accidents released by the Ministry of Economy, Trade and Industry to get a picture of how accidents have occurred. As we proceeded with the research, we learned how engineers had studied hard and accumulated knowledge on safe practices. We also visited ammonia-related facilities and interviewed people engaged in ammonia-related work. The safety measures and maintenance techniques thus derived will be incorporated into the design of ammonia-fueled vessels and utilized in their operation.

––

Do you face any problems connected to the development of ammonia-fueled vessels?

Of course, there are some technical problems, and unexpected things occur on a daily basis, but there are a total of 50 to 60 project team members participating from our company and other organizations. When we discuss solutions, ideas about potential solutions are put forward. I really appreciate those inputs.

––

What do you want to achieve with ammonia-fueled vessels?

Safety. That’s the first thing I want to achieve. Any kind of accident will create the impression that using ammonia fuel for ships may be technologically premature, which will delay decarbonization efforts not only at NYK but also in areas worldwide.

––

What makes you happy about working as an NYK marine engineer?

NYK launched the world’s first ammonia-fueled vessel, Sakigake, and is exploring every possible way to achieve the goal of decarbonization. I don’t think many companies can do that. Thanks to the ambidextrous management set forth in the company’s management plan, I can participate in refining transport activities and developing new technology. That’s the joy of being part of this company.

Today, we live in an age in which we have to take on new challenges while capitalizing on our experiences. We have to sniff out new technologies to determine which are good and which are bad. To hone our “sense of smell” as engineers, we have no choice but to enhance our technological capabilities by accumulating small efforts to develop new ideas for saving fuel and enhancing safety. I believe our efforts to refine our skills and expertise will enable us to cope flexibly with new challenges.

––

Do you have any advice for younger people hoping to become full-fledged marine engineers?

I am now working on ammonia-fueled vessel projects, but seven or eight years ago, ammonia was not even considered a source of energy. This kind of thing may also occur in the coming years, and a new technology to generate economical and environmentally friendly power may be developed. The fundamental mission of maritime shipping is to transport customers’ goods safely and stably, and we must respect and value time-proven traditional maritime practices and skills. However, at the same time, there is a growing demand for marine engineers who are sufficiently sensitive to adapt flexibly to emerging technologies. It’s no easy task to meet those needs, but such challenges could provide an opportunity to become an unprecedented, unique success. Good luck to younger mariners! They have the mariner’s spirit.

This article was re-edited from the Special Issue of KAIJI PRESS published on March 25, 2025.