NYK Collection: Pure Car and Truck Carriers — Like Giant Multistory Parking Lots Floating at Sea!

Released : Dec. 02, 2025

Updated : Dec. 03, 2025

Sakura Leader, an NYK LNG-Fueled Pure Car and Truck Carrier

The NYK Group operates a wide variety of vessels. In this series, “NYK Collection,” we introduce the various types of ships that play vital roles at sea, even though they are not widely known to the general public. In this fourth installment, we focus on pure car and truck carriers (PCTCs), vessels specialized in transporting vehicles.

Transporting New and Used Vehicles Across the Seas

Japanese vehicles enjoy worldwide acclaim. While many new vehicles are exported overseas, used cars have also surged in popularity in recent years. During your travels abroad, you may have come across classic Japanese trucks or buses in use. At the same time, Japan has seen an increase in the import of foreign vehicles. These cross-ocean journeys are made possible by PCTCs.

PCTC stands for “pure car & truck carrier” — vessels designed specifically to transport passenger cars and trucks. Historically, fleets included pure car carriers (PCCs) dedicated solely to passenger cars, but those have largely fallen out of use.

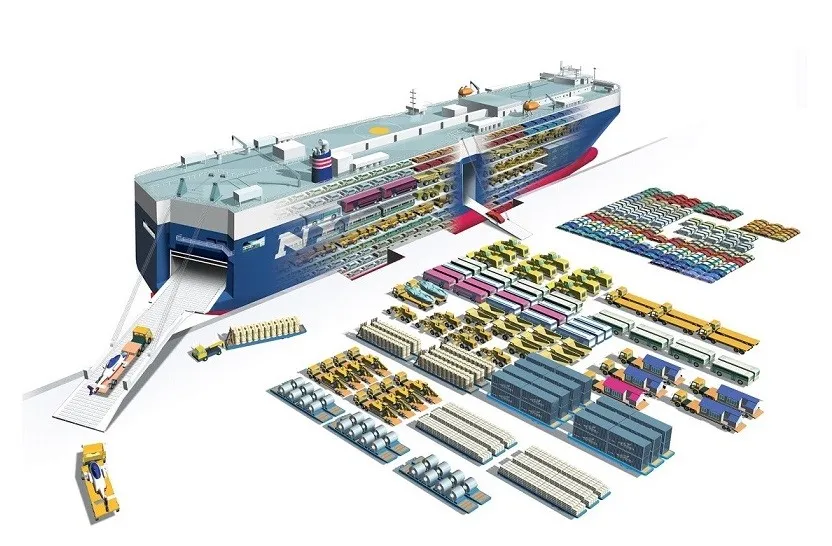

Although “pure” implies exclusivity for cars and trucks, these vessels can carry much more. In addition to drivable vehicles such as construction machinery, agricultural equipment, and airport buses, these ships also transport non-drivable cargo like helicopters, boats, tires, containers, and even wind turbine blades, often loaded onto trailers.

PCTCs transport a wide variety of cargo, not only cars and trucks

Currently, the NYK Group operates approximately 120 PCTCs, giving it the world’s largest share in operation (15.1% as of April 2025). This scale underpins NYK’s strong competitive edge in the global automotive logistics network.

PCTCs are enormous ships—so colossal that when you stand beside one, you can only look upward in awe, as its height rivals that of an 11-story building.

Routes for these vessels vary depending on the circumstances. For example, a typical voyage might see a ship depart Japan for its first export destination, unload part of its cargo, then load new cargo before proceeding to the next port. Such ships frequently call at multiple ports sequentially, often returning to Japan carrying imported vehicles. Operations are meticulously planned to maximize efficiency and minimize waste.

PCTCs carry many types of cargo

Reference: https://www.nyk.com/english/news/2021/20210902_01.html

The Birth of PCTCs from a Growing Auto Trade

Before the advent of PCTCs, cars were loaded individually by crane along with other cargo — a process that was time-consuming, risked damaging vehicles, and was inefficient, given that cars cannot be stacked in the way general cargo can.

As automobile exports surged in the 1960s, the Ro-Ro (Roll-on/Roll-off) method was devised. Ships were equipped with rampways — sloped passages allowing cars to drive on and off the vessel. These vessels featured multiple decks for vehicles, enabling the transport of over 1,000 units per voyage.

After unloading cars at export destinations, these vessels would load bulk cargo such as grain for the return voyage. Known as “car-bulkers,” they began operating in Japan in the mid-1960s, carrying wheat, coal, and ore from the U.S. to Japan.

However, demand for dedicated car carriers grew. Residue from bulk cargo could damage car paint, and delays in cargo collection disrupted loading schedules.

In 1970, Japan’s first oceangoing PCC was built. More followed, growing larger until vessels capable of carrying 6,000 cars emerged.

Caption: Jintsu Maru, NYK’s first pure car carrier, completed in 1970

Courtesy of the NYK Maritime Museum

By the 1980s, as local production of small cars increased and exports of heavy machinery, trucks, and agricultural equipment rose, PCTCs evolved to accommodate taller vehicles. Since the 2010s, newly built PCTCs have become eco-ships, designed to conserve energy and reduce CO₂ emissions.

Cargo includes construction vehicles, railway cars, and even wind turbine blades. Non-self-propelled cargo is transported using roll trailers.

A 12-Deck Parking Space Prioritizing Safety

Imagine a PCTC as a “floating multistory parking lot” — a concept perfectly embodied by NYK’s PCTC Pleiades Leader.

NYK’s PCTC Pleiades Leader

This vessel can carry up to 6,430 passenger cars. With dimensions of 199.94 meters in length and 32.26 meters in width, the ship is optimized for port facilities and docks, and for passing through the old Panama Canal, ensuring versatility on international routes. From the keel to the top of its antenna, Pleiades Leader reaches 52.6 meters in height, yet only 8–9 meters of the vessel are submerged when fully loaded. This is because the bulky cargo PCTCs carry is also very light, in contrast to bulk carriers or tankers that transport heavy commodities like iron ore and crude oil.

Due to their tall structures, these ships are particularly susceptible to crosswinds. Specialized navigation techniques — such as adjusting ballast water and accounting for wind drift — are essential when setting course to maintain stability.

The cargo decks span 12 levels, with crew accommodations and the bridge consolidated at the stern. The bridge is positioned at the top, an arrangement that maximizes cargo space and ensures visibility.

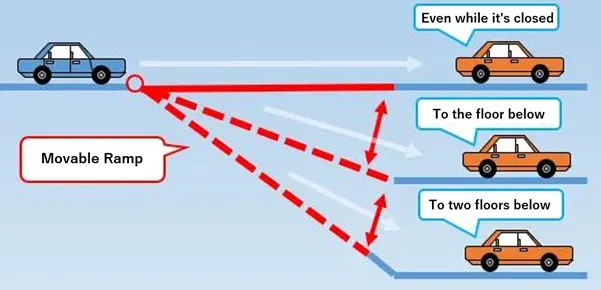

Vehicles primarily enter and exit via the stern ramp (quarter ramp), but side ramps (center ramps) are also used for efficiency. Cars drive onto the fifth deck and then use sloped passages to reach their designated deck. A notable feature is the “movable ramp,” an adjustable slope that can connect to the same level when horizontal or to lower decks when inclined, enabling efficient vehicle movement.

Stern ramp installed at the rear of the vessel

Movable Ramp (Adjustable Ramp)

By adjusting the angle of the movable ramp, vehicles can be efficiently transferred to the target deck.

Two of the decks have adjustable ceiling heights. While most decks are 2.1–2.2 meters high, the fifth and seventh decks can be raised to 5.1 meters. This is accomplished in three stages using special lifting equipment stationed on board.

Special lifting vehicle, called a “liftable car,” used to raise the ceiling height

Large ventilators prevent exhaust buildup. Along with stringent fire-hazard controls, hundreds of smoke detectors, fire extinguishers, and water pipes serve as critical safety precautions.

Stowage: A Collaboration Between Land-Based Experts and Port “Gangs”

One of the most notable aspects of pure car and truck carriers is the seamless coordination between professional planning teams and expert stowage crews.

The process begins with meticulous planning. To tightly load vehicles of various sizes across 12 decks, planners must carefully consider the orientation and sequence of each car. They take into account fixed obstacles such as pillars, the locations of movable ramps, and ceiling heights. Moreover, since not all vehicles are destined for the same port, land-based planners design detailed loading and unloading sequences for each port to ensure safety and maximize efficiency.

Once planning is complete, the stowage operation begins. This phase relies on teams known as “gangs” provided by local stevedoring companies. Despite the term “gang” conjuring images of criminal groups, its origins stem from older meanings like “march” or “row.” In modern Dutch, it even refers to a “passage.” From these roots, maritime terminology evolved to refer to dockside work crews as “gangs,” and the passage connecting ship and shore as a “gangboard” or “gangway.” Each gang typically consists of 15 to 25 members, and during busy times, more than five gangs may work simultaneously.

Within these gangs, there are various roles. First, the “yard driver” transports vehicles from the yard to the designated deck within the ship. They follow strict rules, such as maintaining a speed of 20 km/h and a 15-meter gap between vehicles. After parking on the assigned deck, they immediately return to the yard for the next vehicle. The driver who operates the shuttle car that takes yard drivers back outside the ship is called the “ashiguruma driver.”

Once a vehicle is on board, a “spot driver,” guided by a “signalman,” maneuvers the vehicle into its exact position on the deck. The required clearances are remarkably tight: 30 cm at the front and rear, and just 10 cm on the sides — a testament to the skill involved.

Once positioned, the vehicle is secured using belts and metal fittings called “graspers,” which attach to numerous lashing holes in the floor. The workers who perform this task are known as “lashers.” Proper lashing ensures that even in rough seas, vehicles remain securely fastened and do not collide with one another. Lashing holes are also found on the ship’s internal ramps, allowing every space to be used efficiently.

Once loading is complete, the gangs return to shore, while the vessel’s crew continues to diligently inspect the security of each vehicle daily throughout the voyage.

Continual Evolution of PCTCs

Sumire Leader, LNG-fueled pure car and truck carrier delivered in 2023

NYK’s PCTCs continue to evolve. Operational efficiency has improved through big data analysis of wind, waves, speed, fuel consumption, and weather, enabling optimized routes and arrival times. Stowage planning systems now algorithmically replicate planners’ expertise, reducing planning time from up to six hours per vessel to 2.5 hours. Fleet allocation has also shifted from manual expertise to AI-driven optimization.

Moreover, all 20 newly built vessels in recent years are LNG-fueled, reducing emissions of CO₂, NOₓ, and SOₓ. In 2021, NYK introduced the world’s first battery-hybrid PCTC combining LNG fuel and batteries, cutting SOₓ emissions by about 90%, NOₓ by 85%, and CO₂ by 25% compared to conventional heavy-fuel vessels.

Through advanced technology, skilled professionals, and environmental stewardship, NYK’s PCTCs are set to continue their vital role in connecting ports worldwide.

Auto Advance, a battery-hybrid LNG-fueled pure car and truck carrier